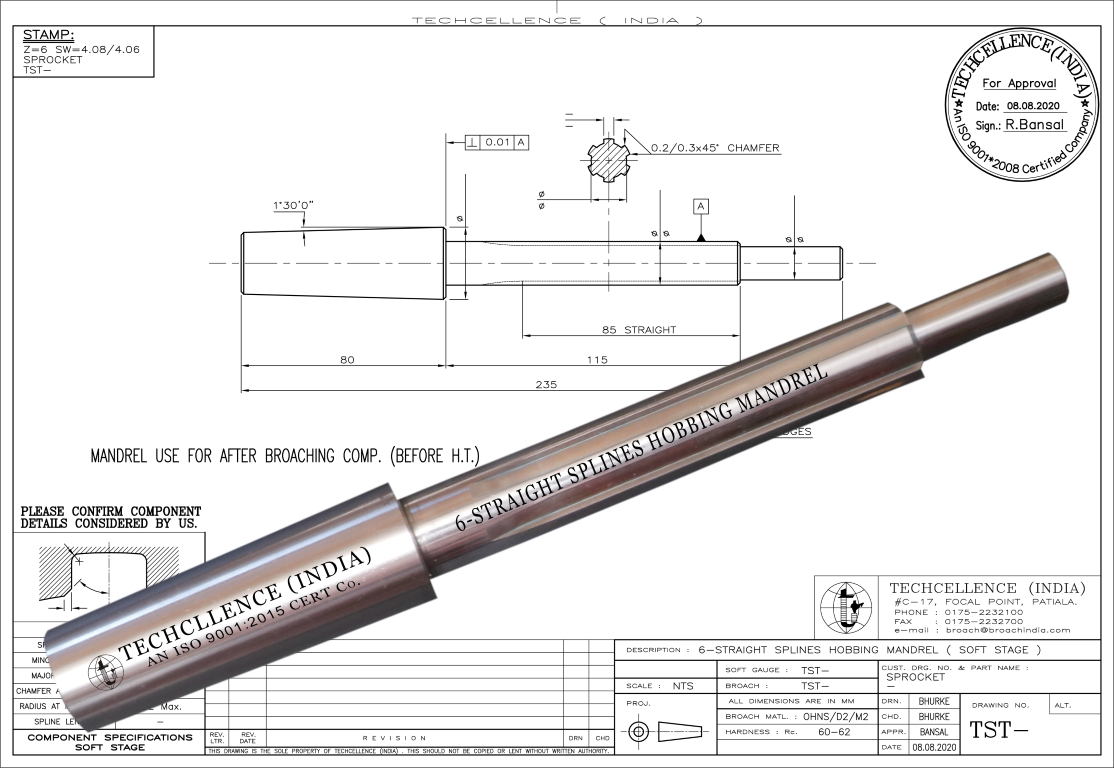

Hobbing Mandrels - Gear Hobbing Shaving Mandrel - Gear Hobbing Mandrels

We make Spline Hobbing Mandrel with 0.05 run out to cut gears in respect to spline concentricity.

These Hobbing Mandrels are used where concentric relation is required with respect to internal splines are made with the help of spline Hobbing mandrels.

We design, manufacture and export wide range of spline mandrels as per world standards i.e. ANSI B 92, JIS, DIN 5480, 5482, HES etc according to customer specifications. Spline mandrels check phase run outs with respect to spline in components. Spline Mandrels locate the Splined Components on Pitch Circle Diameter (PCD) of Splines or on the Major Diameter of internal splines, serrations or involute splines. The component checks the accuracies like face run out, OD run out with respect to PCD or major diameter. Spline Mandrels are invariably employed for finishing machining operations w.r.t PCD or major dia.

These Mandrels are made as per DIN standard. Mandrels are coated as per customer requirements. We have earned a name of trust and quality worldwide in manufacturing and export of Spline Mandrel manufacturers in India. Several manufacturing and trade resources list us as their most trusted manufacturer exporter in the list of broaches cutting tools.

Every mandrel has a smooth finish, precise design and high strength. Raw material used for every mandrel is M-2 (6.5.2).

Happy Clients

We manufacture products as per customer specification & requirements.