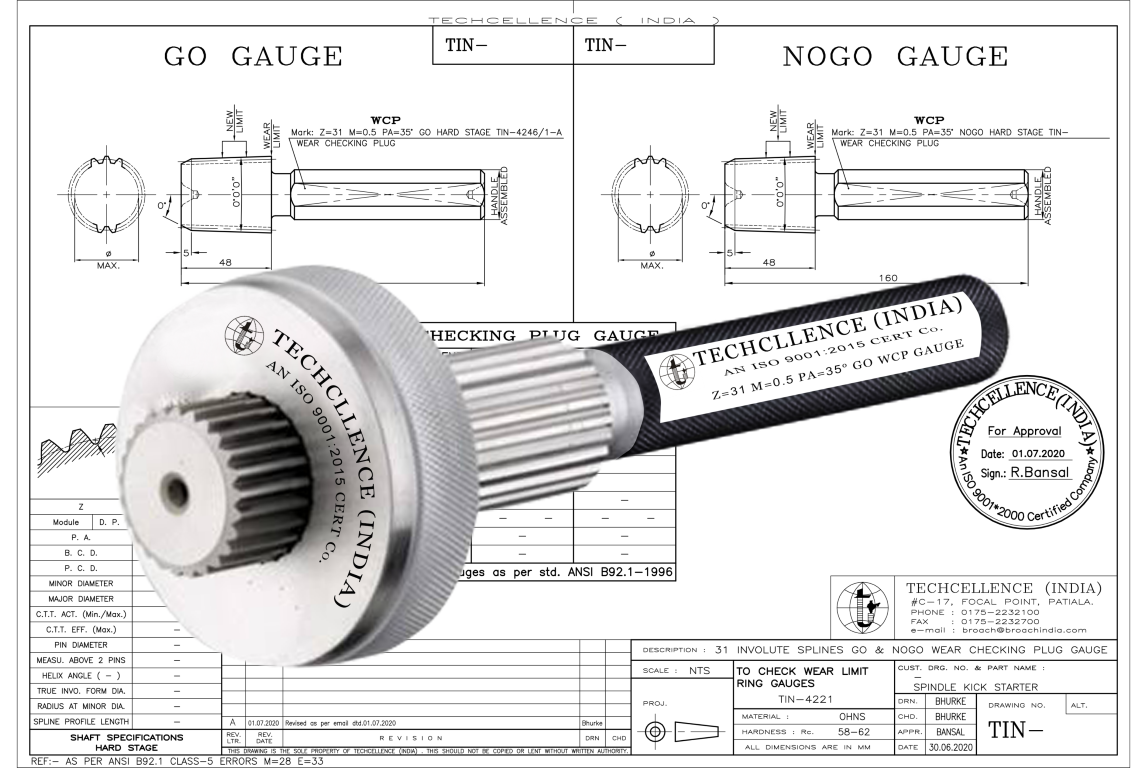

Wear Limit Checking Gauges

Wear Limit gauging is a method of checking dimensions in which a fixed gauge is applied to the work in order to determine whether a given component lies within its limits. Gauges are inspection tools of rigid design, without a scale, which used to check the dimensions of manufactured components.

Gauges do not indicate the actual value of the dimensions of the component. They are only used to check whether the inspected part has been made within the specified limits.

Thus, a limit gauge, unlike a conventional measuring tool, simply determines whether, the part is inside or outside the tolerance zone. The gauge neither measures a value of dimensions, nor shows the value of error evolved in the component. It simply checks that part is correct or not.

Happy Clients

We manufacture products as per customer specification & requirements.