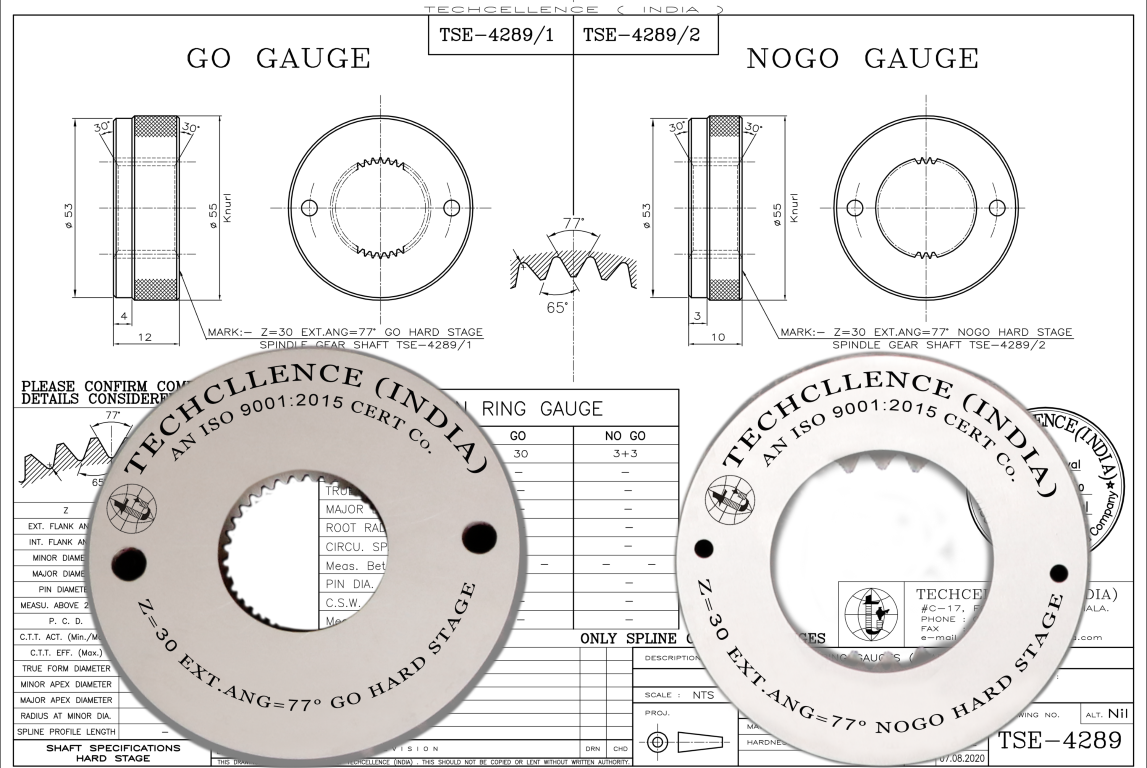

Serration Ring Gauges

We manufacture Serration Ring Gauges: – These gauges are created with our vast experience of design & are crafted with high accuracy, We make gauges from Diameter 3 mm to 270 mm 0.5 module to 25 module.

Ring type spline gauges are used for checking external splines. These gauges are used for Checking parameters like profile accuracy, indexing accuracy, major diameter & minor diameter and to control Measurement over pins Sizes of splined components on a production line. So for checking the dimensions GO and NO GO gauges are simple and reliable for ensuring the supply is as per specification & requirement.

In the case of big-size gauges, we can do a lot to reduce the weight reduction of the gauges. Please, follow the link to how we make these gauges lighter.

In case of emergency, we can ship the material in 3 working days also.

Our gauges are made of High-quality material Which is heat-treated & we also adopt sub-zero treatment to lessen the weather shrinkages & is inspected with our experienced team with the best facilities to ensure the perfect size required.

The “GO” ring is a composite gauge having a full complement of teeth and is used to inspect maximum material conditions. minimizing the chance of fit interference. In other words, if the part fits the “GO” gage. there is a high probability of assembling with its mate later. The “GO” gage cannot measure the looseness of the size of the part being gaged. It can only reject those parts that will not enter the “GO” gage.

The “NO GO” gauges do not have a full complement of teeth. but rather only two diametrically opposed groups of teeth. It is used to inspect minimum material conditions, thereby, governing the maximum looseness. If the spline part is thin-walled. or tubular. or heat treated. It is desirable to I try the ‘NO GOI’ gage in at least two places 90 degrees apart. An ova part. for example. may enter the ‘NO GO” gage at the low point, but not the high. Ovality reduces the chances of getting the full use of all the teeth in the final assembly. At this point, a few definitions would be in order.

Spline gauges provide a quick method of inspecting involute splines, serration splines, and straight sided splines. “Go” gauges are still indispensable for inspecting constructional feasibility. “Not go” gauges, on the other hand, only represent a limited means of inspection.

Happy Clients

We manufacture products as per customer specification & requirements.